The Future of 3D Printing

Why Automation Like the Infinity Flow S1 is the Next Big Thing

As 3D printing continues to evolve, the industry is moving toward greater automation and efficiency. These trends are not only making 3D printing more accessible but also enabling users to achieve higher levels of precision, reliability, and productivity. At the forefront of this shift is the Infinity Flow S1, a device designed to automate filament management, reduce downtime, and enhance the overall 3D printing experience. Here’s why automation, and products like the S1, represent the future of 3D printing.

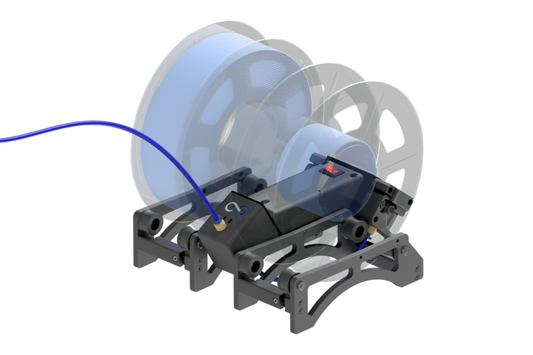

The Infinity Flow S1 is an advanced 3D printing accessory designed to automate filament switching, preventing print failures due to filament runout. It seamlessly transitions between spools, ensuring continuous, high-quality prints without manual intervention.

The Push Toward Automation in 3D Printing

Increasing Complexity and Scale of Projects

As 3D printing technology matures, users are tackling more complex and larger-scale projects. Whether it’s in industries like aerospace, automotive, or healthcare, the need for precision and reliability is critical. However, these demands often come with challenges such as managing multiple spools of filament, avoiding print failures, and reducing material waste. Automation is the answer to these challenges, allowing users to focus on design and production rather than the intricacies of printer management.

Reducing Human Error

Manual processes in 3D printing, such as filament changes, are prone to human error. Even experienced users can make mistakes that lead to print failures, wasted materials, and lost time. Automation reduces these risks by standardizing processes and ensuring consistent quality across prints. Devices like the Infinity Flow S1 automate filament switching, which not only prevents common issues like filament runout but also enhances the reliability of long and complex print jobs.

Efficiency and Productivity Gains

In a world where time is money, the efficiency gains offered by automation cannot be overstated. Automated systems like the Infinity Flow S1 enable continuous printing without the need for constant monitoring, allowing for higher productivity. This is particularly important in professional environments and small-scale production settings, where maximizing output is crucial. As 3D printing scales up, the demand for such automated solutions will only increase.

This image features multiple Infinity Flow S1's installed on 3D printers in Purdue University’s Mechanical Engineering Printing Lab. The S1 automates filament switching, enabling students to focus on their projects without the risk of print failures due to filament runout, enhancing the learning experience in a hands-on environment.

Why the Infinity Flow S1 is Leading the Way

Automated Filament Management

The Infinity Flow S1 addresses one of the most tedious aspects of 3D printing—managing filament. By automatically switching spools when one runs out, the S1 ensures that your print jobs continue uninterrupted, reducing the chances of failure. This feature is especially valuable for long prints, where the risk of running out of filament midway through a project is high.

Broad Compatibility and Flexibility

Unlike some automation tools that are designed for specific printer models, the S1 is built to work with a wide range of FDM 3D printers. This makes it a versatile option for anyone looking to upgrade their existing setup. The S1’s modular design also means it can adapt to different workflows, making it an ideal choice for both hobbyists and professionals who need a reliable, scalable solution.

Reducing Material Waste

Sustainability is becoming increasingly important in manufacturing, and 3D printing is no exception. The S1 helps reduce material waste by ensuring that each spool of filament is used to its fullest before switching to the next. This not only saves money on materials but also aligns with broader environmental goals by minimizing waste.

Positioned for the Future

As the demand for more complex and large-scale 3D printing grows, so too will the need for automation. The Infinity Flow S1 is positioned to meet these needs, offering a solution that not only improves the current state of 3D printing but also anticipates future trends. By focusing on automation, Infinity Flow is setting the stage for more efficient, reliable, and user-friendly 3D printing experiences.

Conclusion

The future of 3D printing is moving toward greater automation, and the Infinity Flow S1 is a perfect example of this trend in action. By automating filament management and offering a reliable, scalable solution, the S1 is helping to push the boundaries of what’s possible in 3D printing. As the industry continues to evolve, tools like the S1 will become essential for anyone serious about 3D printing, from hobbyists to industrial users.

Interested in learning more about how the Infinity Flow S1 can transform your 3D printing setup? Click here to explore its features and see how it fits into the future of 3D printing!