Avoiding Common 3D Printing Pitfalls

How the Infinity Flow S1 Can Save Your Prints

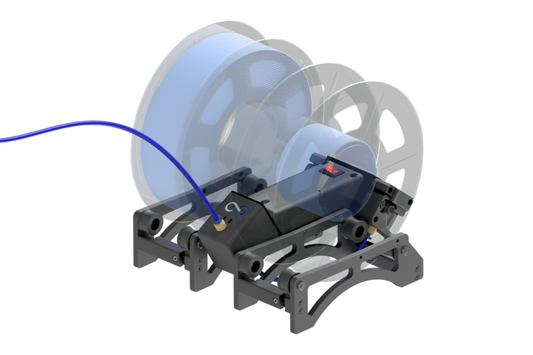

3D printing offers endless possibilities for creators, but it also comes with its share of challenges. Among the most common pitfalls are filament runout and issues arising from manual spool changes, both of which can lead to failed prints and wasted material. The Infinity Flow S1 is designed to tackle these problems head-on, ensuring consistent print quality and reducing the frustration that often accompanies 3D printing. Let’s explore how the S1 addresses these common issues and keeps your projects on track.

Common 3D Printing Pitfalls

- Filament Runout

- The Problem: One of the most frustrating scenarios in 3D printing is when a print fails because the filament runs out mid-print. Without a system in place to handle this, the printer will continue moving, but with no material being extruded, leaving you with a partially completed and unusable print. This not only wastes filament but also costs valuable time, especially with long print jobs.

- Impact: Filament runout can lead to significant material waste and can be particularly problematic during overnight or long-duration prints when monitoring is not feasible.

- Manual Spool Changes

- The Problem: For larger prints or projects that require more filament than a single spool can hold, manual spool changes are necessary. However, manually pausing the print, changing the spool, and resuming the print introduces several risks. There’s the possibility of misalignment, improper feeding of the new filament, or even introducing air gaps, all of which can compromise print quality.

- Impact: Manual spool changes can cause layer shifts, weak points, or inconsistencies in the print, leading to lower overall quality and potential print failure.

How the Infinity Flow S1 Prevents These Issues

1. Automated Filament Switching- The Infinity Flow S1 eliminates the issue of filament runout by automatically switching to a new spool when the current one runs out. This feature ensures that your printer continues to work uninterrupted, even during long prints. The S1 detects when the filament is about to run out and seamlessly transitions to the next spool, preventing any gaps or pauses in the print.

- Example: Imagine you’re printing a large, intricate model that requires more than one spool of filament. With the S1, you can start the print and walk away, confident that the system will manage the spool change without interrupting the print, ensuring a flawless final product.

This GIF demonstrates the Infinity Flow S1 in action, automatically switching from black to white filament when the black spool runs out. The seamless transition ensures uninterrupted printing and highlights the S1’s ability to handle filament runout with reliability.

2. Consistent Print Quality

- By automating the spool-changing process, the S1 removes the human error factor that often accompanies manual changes. The system ensures that the new filament is fed correctly and consistently, maintaining the quality and integrity of the print. This means no layer shifts, no air gaps, and no weak points, leading to a stronger, more reliable final product.

- Example: For professionals or hobbyists working on detailed models or prototypes, the S1 guarantees that each layer is printed perfectly, even when switching between spools. This is crucial for maintaining the structural integrity of the print, especially in engineering or architectural models where precision is key.

This 3D Benchy demonstrates the Infinity Flow S1’s ability to perform smooth filament switches, transitioning seamlessly between black and white filament rolls. Note: The S1 is not a color changer; the two-tone effect is to highlight its precise filament management capabilities.

3. Minimizing Waste

- The S1 not only prevents print failures due to filament runout but also reduces material waste. By ensuring that each spool is used to its fullest before switching, the S1 helps you get the most out of your filament, making your 3D printing process more cost-effective and environmentally friendly.

- Example: If you often find yourself with spools that still have some filament left but not enough for a full print, the S1 can help by automatically using up these partial spools before moving on to a new one, ensuring that no filament goes to waste.

The Infinity Flow S1 is shown completing a 3D print with empty filament rolls, highlighting its ability to use every last bit of filament. This efficient filament management ensures that no material goes to waste, making the S1 an essential tool for achieving cost-effective and sustainable 3D printing.

Conclusion

The Infinity Flow S1 is a must-have upgrade for anyone serious about 3D printing. By addressing common issues like filament runout and the risks associated with manual spool changes, the S1 ensures that your prints are completed successfully, with consistent quality and minimal waste. Whether you’re a professional working on critical projects or a hobbyist looking to improve your printing experience, the S1 can save you time, money, and frustration.

Ready to safeguard your prints against these common pitfalls? Visit our website to learn more about the Infinity Flow S1 and see how it can transform your 3D printing experience today!