Official Launch: July 15th - 10:00AM EST

Works With Most 3D Printing Setups

No Sensors. No Wiring. Just Physics

1. Filament enters the cutter’s tube

2. Bent ends or tangles gets caught in the inlet tube.

3. The tension pulls it down, cutting off the bad end.

4. The S1 reloads the next spool and keeps your print running.

New Features Since Beta Launch

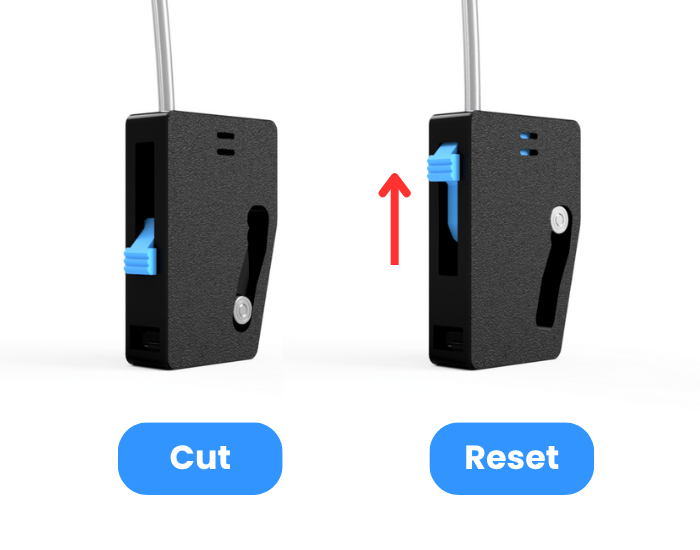

Spring-Assisted Cutting Blade

Ensures clean, consistent cuts every time.

- Requires 3X less force to complete each cut

- Prevents grinding/skipping gears/extruder

- Easy to reset after each cut

Two Sensitivity Options

Choose the option that is most reliable with your setup.

High Sensitivity (level 1): Makes it easier to trigger a cut — ideal for extruders that previously struggled to finish cuts.

Low Sensitivity (level 2): Helps prevent accidental cuts or false triggers in high-tension systems.

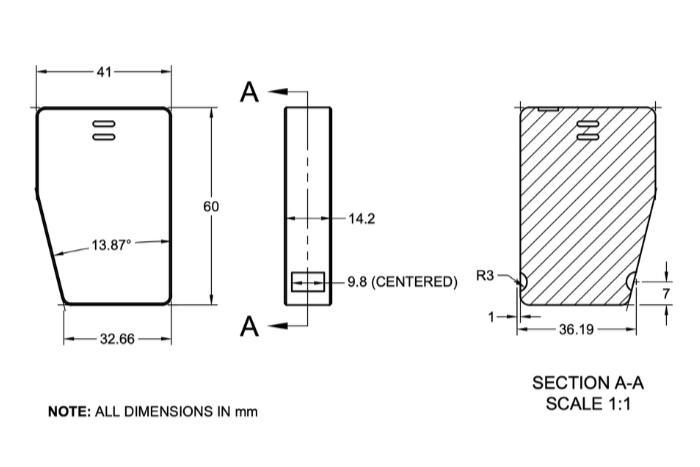

Designed to be Universal

Compatible with a wide range of 3D printing systems that use 1.75 mm filament, including:

- Automatic Filament Re-loaders (like the S1)

- Direct-to-extruder Setups

- Many AMS/MMU style units